Overview - Graphite as a Critical Mineral

Affordable lithium-ion batteries (LiBs) have revolutionized the world by powering our mobile electronics. With the soaring potential of electric motor automobiles, heavy transport vehicles, and other energy storage systems, demand for batteries is expected to rapidly grow.

As the United States looks to the opportunity of domestic battery manufacturing as this market grows, one major challenge is that we are not a large producer of these minerals, including lithium, manganese, cobalt, and graphite - all important components of today’s lithium-ion batteries LiBs. The United States is import-reliant (imports greater than 50 percent of annual consumption) for 31 of the 35 minerals designated as “critical” by the Department of the Interior.

These commodities, including graphite, qualify as “critical minerals” because each has been identified as a non-fuel mineral or mineral material that is essential to the economic and national security of the United States. Each has a supply chain vulnerable to disruption and serves an essential function in the manufacturing of a product - the absence of which would have significant consequences for the economy or national security.

China leads the lithium-ion battery supply chain and is the largest producer and consumer of anode material, battery components, and the lithium-ion batteries themselves. The global production of graphite and spherical graphite (SPG) is currently dominated by China.

Spherical Graphite Overview

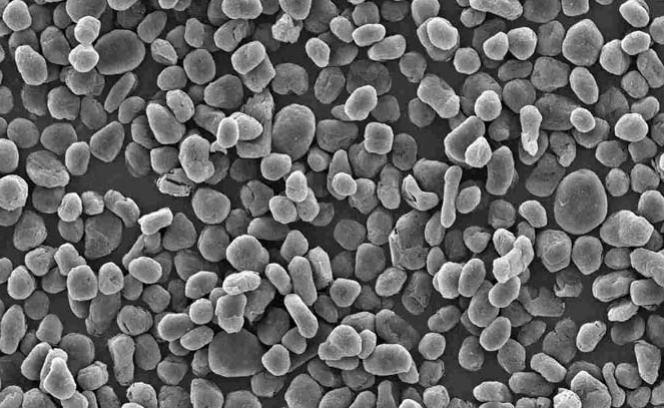

The global demand for cost-effective energy storage solutions and home energy storage continues to drive the growth of the graphite flake market. Typically, flake graphite is shaped into a rounded, spherical shape by a mechanical attrition process. The rounded shape of SPG allows for more efficient packaging of particles in a LiB anode, which increases the energy and recharge capacity of the LiB. Spherical graphite is a crucial ingredient in the efficient operation of lithium-ion batteries. SPG is the key component of the anode of a LiB which without, the LiB would not function.

Historically SPG has been derived from synthetic graphite, a significantly more costly option when compared against natural flake graphite (NFG).

Purification and Coating

The spheroidical graphite is then purified to remove deleterious elements including SiO2, Iron, Sulfur, and other metal elements. Various purification techniques are used in this process. These include aggressive acid purification with hydrofluoric acid, as well as thermal purification using high-temperature furnaces. Both of these methods have their advantages and disadvantages.

Aggressive acid purification is a low cost, effective method of purification, but due to the nature of the acids used, including hydrofluoric acid, they present a toxic and dangerous working environment, as well as an environmental management challenge. Thermal purification is an electrical thermal process which is fairly expensive compared to acid purification, but is significantly safer and does not impact the environment.

After purification, Purified SPG is coated to assist with improving the surface and area of the particles. Many LiB manufacturers used their own proprietary technology for coating. The coated, purified SPG is then packed into the shape of the anode required for the LiB batteries.

Spherical Graphite Market Outside of China

With the transition of the world to a clean energy platform, many LiB manufacturers are actively seeking alternative supply options. A number of companies with flake graphite mining projects outside of China have furthered their development of spherical graphite with an aim to become the first commercial-scale producer in the rest-of-world (ROW) market.

Barriers to entry for spherical graphite production are high, especially in the ROW, which has previously found it hard to compete with China’s lower labor and energy costs and its less stringent environmental restrictions. Although environmental costs are rising in China, the traditional method of flake graphite processing to produce spherical graphite, including the use of hydrofluoric acid and other strong acids, continues. ROW producers looking to distance themselves from this method have looked to develop their own proprietary methods of purification. It is essential to the economic and national security of the United States to scale-up to commercial production at costs competitive with China.